CUSTOM ACOUSTIC ENCLOSURES FOR INDUSTRIAL GENERATORS

Performance and Durability. On time.

In a world where noise control standards are increasingly stringent, we create soundproof enclosures that meet the challenges and constraints of each project. And we achieve this by offering the shortest manufacturing lead times in the market, without compromising on quality or safety.

Our products: Custom solutions that deliver

Regardless of your generator model, our engineers and designers will design an enclosure perfectly adapted to your environment.

Enclosures for industrial, commercial, and institutional generators

We design and manufacture walk-in and tight-fit enclosures, designed to perform in the most demanding environments and withstand extreme weather conditions.

Data centres

Hospitals and healthcare facilities

Plants and manufacturing installations

Oil, mining, and construction sites

Our unique noise reduction methods deliver optimal acoustic control and meet the highest industry standards. In addition to reducing noise pollution, they ensure on-site safety.

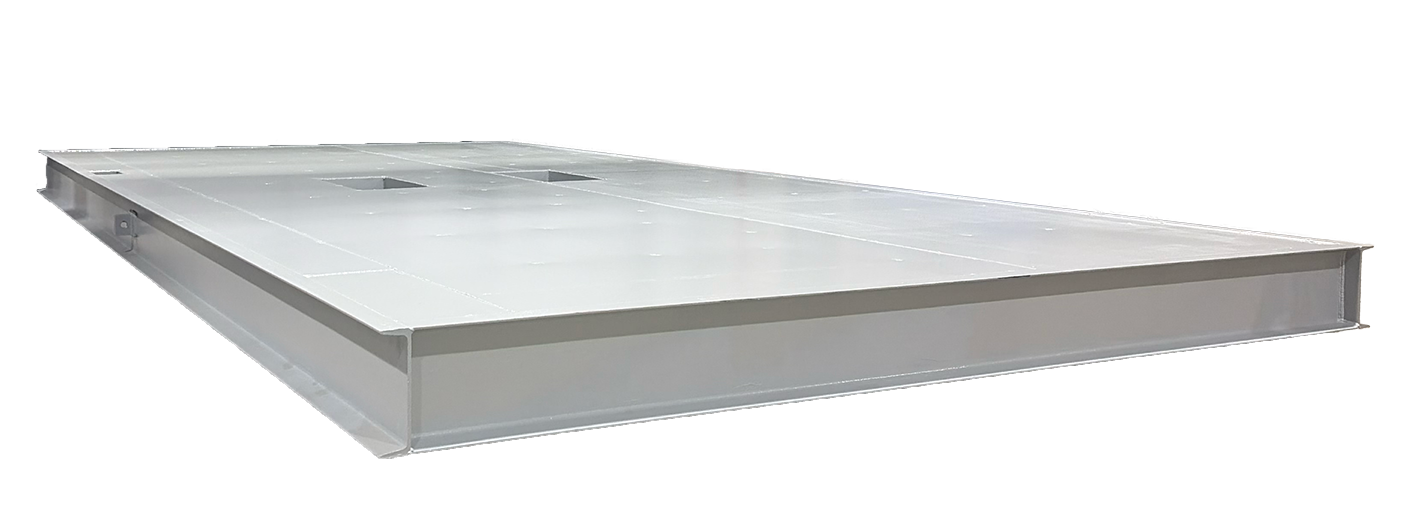

Sub-base tanks

Proud to offer turnkey generator enclosure solutions, we manufacture our own ULC-certified sub-base tanks. Integrated into your acoustic enclosure, this complementary product powers your generator for 24 to 48 hours.

Our services: from design through installation, no compromises

Every project begins with a thorough analysis of your acoustic and mechanical requirements. Our design and manufacturing services ensure compliance with the most stringent standards, dimensional specifications, and equipment requirements.

2D and 3D Design

Our production team ensures compliance with the most demanding specifications. Our welding processes are CWB-accredited, ensuring superior quality that meets industry standards.

Cutting-edge Manufacturing

Loading for Transport

Our reliable, safe, and optimized truck loading solution relies on high-performance overhead cranes. This capability ensures quick and effortless handling of your enclosure while preserving its integrity. Our expertise translates into a controlled loading process that facilitates transport and meets the highest safety standards.

About Vibra-Sil

Our mission: Pushing the boundaries of silence

For 40 years, Vibra-Sil has been recognized for its ability to design and manufacture high-performance acoustic solutions tailored to the needs of industrial, commercial, and institutional sectors.

Combining precision engineering and manufacturing expertise, our team of over 100 employees brings together committed individuals at the forefront of their trade: from design to assembly, including welding, engineering, painting, and customer service.

Today, with the support of new shareholders, the company is entering a new chapter in its history, building on its manufacturing heritage and culture of innovation to continue its growth. Our values of respect, integrity, and loyalty guide every decision we make and shape the collaborative approach we take with clients and suppliers alike.

More than ever, our teams are committed to upholding the reputation for quality associated with the Vibra-Sil name.

Modern facilities, 100% Quebec manufacturing

Our two plants in Beauport and Longueuil span over 100,000 square feet, housing our R&D, 2D and 3D design engineering, as well as production teams. Our overhead cranes accommodate generators of up to 3,500 kW, while our next-generation cutting and bending equipment ensures precise manufacturing without compromise.

These facilities give us complete control over our design and production process, resulting in the fastest delivery times on the market.

Acoustic enclosures perfectly tailored to each project

Exclusive noise reduction technologies

ULC-certified tank manufacturing

CWB-accredited welding processes

Fast delivery